services

Contract development

We offer our clients the opportunity to realize the full product lifecycle, starting from the qualification of the active substance, through the development of technology, production of validation batches, stability studies, and preparation of documentation for drug registration in European and other global markets.

CONTRACT MANUFACTURING

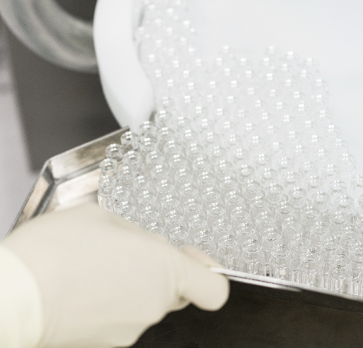

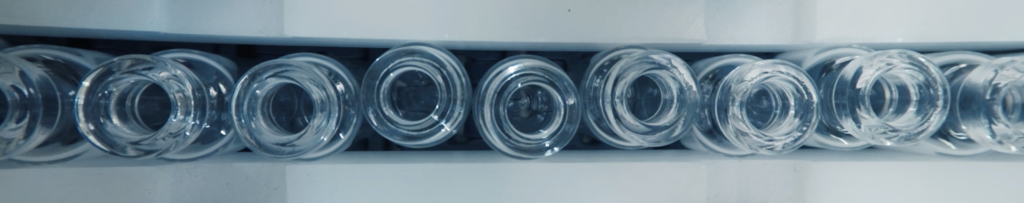

Pharmidea produces generic drugs in sterile vials using various technological methods – lyophilization, aseptic filling, and autoclaving. We offer the development of formulations and technologies for investigational drugs and the production of batches for Phase I-III clinical trials.

Product licensing

We offer ready-to-use technical documentation for sterile drug forms that comply with the latest EMA and ICH guidelines and current industry trends. The quality of the documentation is confirmed by not only European but also international authorities’ opinions. In this process, we are flexible and adapt the content and structure of the documentation according to the requirements of the client’s country.

Quality

” Good Manufacturing Practice " (GMP) certificate

Pharmidea has been a European Good Manufacturing Practice (GMP) certified sterile drug manufacturing company since 2010. Pharmidea has received Good Manufacturing Practice approvals from the authorities of many countries, such as Saudi Arabia, the United Arab Emirates, South Korea, Turkey, Canada, and others.

Quality control

Our quality assurance and quality control teams perform quality checks on raw materials, during the development process, and on final products in accordance with ICH guidelines.

High level equipment

To ensure quality at every step, we use high-end innovative equipment and processes, such as SCF extraction unit, UV/VIS spectrophotometer, high-performance liquid chromatography (HPLC) units.

Contract production

Your product in our factory.

Manufacture of sterile medicines

Pharmidea is the only pharmaceutical manufacturer in Latvia that produces sterile medications in vials. With more than 15 years of experience, expertise, and specialized technologies, we ensure the best results in accordance with European Good Manufacturing Practice standards. Depending on our clients’ needs, our production capacity can reach up to 1 million sterile vials per year.

INVESTIGATION MEDICINAL PRODUCTS

We offer the optimization of investigational medicinal product formulations, the development of technology in the laboratory, production, and the preparation of documentation for phases I-III of clinical trials. We also provide batch packaging and labeling services.

SERIALIZATION

We perform the generation of serialization numbers and the assignment of data matrix codes in GTIN/NTIN/PPN formats.

Printing of the serialization code on cardboard packaging: Packaging sizes from 35x15x50mm to 120x100x180mm,

Print height – 25.4 mm (2D code max. 12.7 mm),

“Integrity Proof” labels on each product box,

Serialization and aggregation of the packaging, transport boxes, and pallets in standard (XML) as well as customized messages and protocols.

| Production technology | Main production steps | Vial size | Production batch size | |

|---|---|---|---|---|

| Cytotoxic products | Non-cytotoxic products | |||

| Freeze-drying | Preparation of intermediate product | 8 ml | up to 1550 | up to 6550 |

| Sterilizing filtration of solution | 10 ml | up to 1550 | up to 5470 | |

| Vials aseptic filling | 30 ml | up to 490 | up to 3430 | |

| Freeze-drying | Depends on freeze-dryer capacity (2) | Depends on freeze-dryer capacity (2) | ||

| Vials aseptic stoppering and sealing | ||||

| Aseptic filling | Preparation of intermediate product | 2 ml | Up to 20 L solution volume (3) | Up to 350 L solution volume (3) |

| Sterilizing filtration of solution | 6 ml | |||

| Vials aseptic filling | 8 ml | |||

| Vials aseptic stoppering and sealing | 10 ml | |||

| 30 ml | ||||

| Terminal sterilisation | Preparation of intermediate product | 2 ml | Up to 20 L solution volume (3) | Up to 350 L solution volume (3) |

| Sterilizing filtration of solution | 6 ml | |||

| Vials aseptic filling | 8 ml | |||

| Vials aseptic stoppering and sealing | 10 ml | |||

| Terminal sterilisation by steam | 30 ml |

(1) Any other size of vials in range 1-100 ml may be considered

(2) Batch size for other vials size may be requested separately

(3) More detailed calculation can be done, knowing the specific size of vials and fill volume

Contract development

Your idea – our experience for the full development process

DEVELOPMENT OF FINISHED DOSAGE FORMS

We offer our clients the realization of the full product cycle, starting with the qualification of the active substance, technology development, production of validation batches, stability studies, and the preparation of documentation for the registration of medicines in both European and other markets.

TECHNOLOGY TRANSFER

Transfer of production technology and analytical methods to/from a third-party manufacturer, in accordance with ICH and EU pharmacopoeia requirements.

Development of an investigational series (IMP) for clinical trials

We offer the optimization of investigational medicinal product formulations, technology development both in the laboratory and under commercial manufacturing conditions, as well as the preparation of technical documentation for phases I-III of clinical trials.

Product licensing

Finished dosage form license

DOCUMENTATION FOR PRODUCT REGISTRATION

Pharmidea offers ready-made pharmaceutical technical documentation developed in accordance with European authorities’ guidelines and requirements.

You will save time and resources in product development by obtaining permission to register it in specific markets.

Learn more about services and cooperation opportunities

partners

Latvijas Organiskās sintēzes institūts

Selectchemie Ag

Logenex Pharm GmbH

Viet Phap

Austell laboratories ltd

Kuwait Saudi Pharmaceutical Industries Co.

AV Medical CZ s.r.o.

Polfa SA Tarchomin

LIDDS AB